Penetration Of Magnetic Flux

Magnetic Particle Inspection is primarily used for the detection of surface breaking discontinuities

and only in ferromagnetic materials. This is because the magnetic fields induced are concentrated

at the surface of the components. However, sub-surface discontinuities may be detected if using

permanent magnets or electrical systems using direct current or half wave rectified current. This

is because the magnetic field penetrates much further into the test specimen in comparison with

MPI test methods which use alternating current which are best at detecting surface discontinuities.

It is unlikely that any form of MPI would be used to detect discontinuities deeper than 2 mm or 3

mm below the surface as flaw detectability decreases with depth. As a general rule, for good

detection rates the depth to width ratio of the discontinuity should be 5:1 or greater.

MPI test equipment, using alternating current (AC) as an output, produces a high density magnetic flux at the surface of the test component. This phenomenon is known as the skin effect (caused by eddy currents). It reduces the penetration of the flux but produces a far stronger flux leakage field on surface breaking, or near surface discontinuities, in comparison with permanent magnets or direct current (DC) test equipment.

The depth of flux penetration is governed by the wave frequency of the alternating current, the conductivity of the test material and its permeability. If any of these variables increase, the depth of penetration will decrease.

Within a conductor, an induced magnetic field is opposed by secondary magnetic fields as a result of eddy currents – producing the skin effect. The depth of penetration is defined as the depth at which the intensity of induced eddy currents reduce to % of the surface value, i.e. 36.8%, 𝑒this may be calculated by

Where:

δ = Depth of penetration

F = Frequency of supply

σ = Conductivity

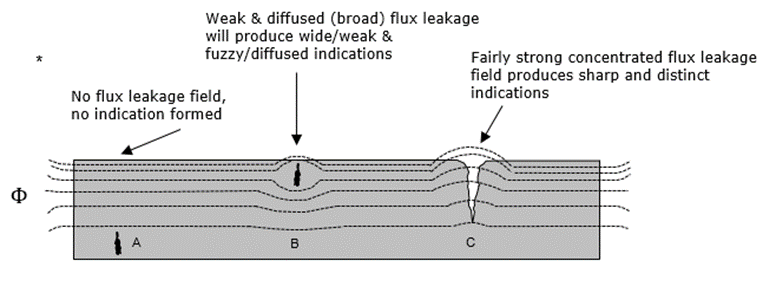

It is difficult to try and interpret very weak and diffused MPI indications which could be from sources other than discontinuities, e.g. caused by rough/uneven surfaces or changes in permeability.

Because of this problem, sub-surface, or body discontinuities, would normally be located by other methods of NDT, assuming the detection of sub-surface discontinuities is a requirement.